Best Practices for Sourcing Reliable CNC Machining Services

In the world of manufacturing and production, CNC machining has revolutionized the way parts are made. From aerospace to automotive, this precision-based technology ensures high-quality results that meet stringent industry standards. However, finding a reliable CNC machining service provider can be daunting. This guide will walk you through the best practices for sourcing dependable CNC machining services, ensuring you get the best quality and value for your money.

How to Identify Trustworthy CNC Machining Service Providers

The Importance of Certifications and Standards in CNC Machining

Success Stories Sourcing High-Quality CNC Machining Services

Tips for Negotiating with CNC Machining Suppliers

Future Trends in CNC Machining Supplier Relationships

How to Identify Trustworthy CNC Machining Service Providers

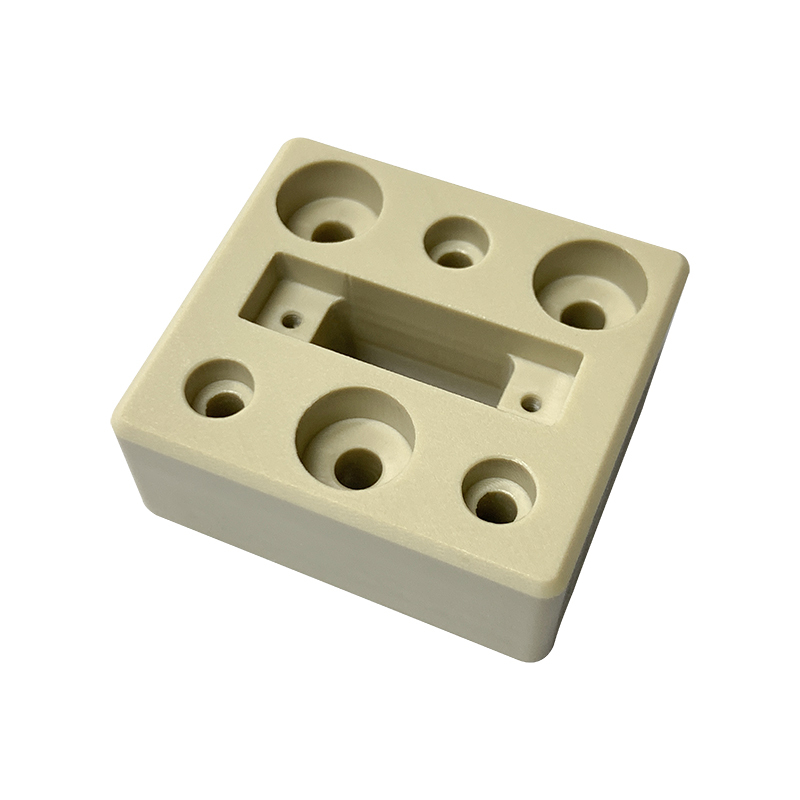

The first step in sourcing reliable CNC machining services is identifying trustworthy providers. Start by researching companies with a solid reputation in the industry. Look for those with positive customer reviews, testimonials, and case studies highlighting their successes. A well-established company with a history of delivering high-quality CNC machining metal parts is more likely to meet your expectations. Another critical factor is the provider's experience and expertise. Check if they have worked on projects similar to yours and have the necessary skills and knowledge to handle your requirements. A provider with extensive experience in CNC machining services will be better equipped to deliver precision and accuracy. Transparency and communication are also vital. A reliable provider will be open about their processes, capabilities, and limitations. They should be willing to provide detailed information about their equipment, materials, and quality control measures. This transparency builds trust and ensures you clearly understand what to expect.

The Importance of Certifications and Standards in CNC Machining

Certifications and standards play a crucial role in ensuring the quality and reliability of CNC machining services. When evaluating potential providers, always check if they hold relevant certifications such as ISO 9001, which demonstrates their commitment to maintaining high-quality standards. Compliance with industry standards is another important consideration. Ensure the provider adheres to the specifications and requirements of your industry. For example, if you are in the aerospace sector, look for providers who comply with AS9100 standards. Certifications and standards give you confidence that the provider follows established best practices and quality control procedures. They also indicate that the provider is dedicated to continuous improvement and staying updated with the latest advancements in CNC machining service.

Success Stories Sourcing High-Quality CNC Machining Services

Hearing success stories from other businesses can provide valuable insights into the reliability of CNC machining service providers. Look for case studies or testimonials from companies that have achieved exceptional results by partnering with a particular provider. These success stories highlight the provider's capabilities and demonstrate their ability to deliver high-quality precision CNC machining services. One example is a leading automotive manufacturer that sourced CNC machining services from a reputable provider. The provider's expertise and advanced equipment allowed them to produce complex metal parts with tight tolerances, resulting in improved performance and reduced costs for the manufacturer. Another success story involves a medical device company that needed custom CNC machined components for their innovative product. The provider's attention to detail and commitment to quality ensured that the components met the stringent requirements of the medical industry, leading to a successful product launch.

Tips for Negotiating with CNC Machining Suppliers

Negotiating with CNC machining suppliers requires careful planning and effective communication. Start by clearly defining your requirements and expectations. Provide detailed specifications, including materials, dimensions, tolerances, and any specific quality standards that must be met. During negotiations, ask about the provider's pricing structure and any additional costs that may arise. Understanding the total cost of the project will help you make an informed decision. Consider requesting quotes from multiple suppliers to compare prices and services. Building a long-term relationship with your CNC machining supplier can also be beneficial. Establishing a strong partnership allows for better collaboration and improved communication. It also opens the door to potential cost savings through volume discounts or other incentives. Finally, don't hesitate to seek recommendations or advice from industry experts or colleagues with experience in sourcing CNC machining services. Their insights can help you negotiate better terms and ensure a successful partnership.

Future Trends in CNC Machining Supplier Relationships

The world of CNC machining is constantly evolving, and staying informed about future trends can give you a competitive edge. One emerging trend is the integration of advanced technologies such as artificial intelligence (AI) and machine learning (ML) into CNC machining processes. These technologies enable predictive maintenance, real-time monitoring, and optimization of machine performance, resulting in increased efficiency and reduced downtime. Another trend is the growing demand for eco-friendly and sustainable manufacturing practices. Many CNC machining service providers are adopting greener processes and using environmentally friendly materials to meet the rising expectations of environmentally conscious customers. The rise of Industry 4.0 is also shaping the future of CNC machining supplier relationships. Industry 4.0 focuses on the digitalization and interconnectivity of manufacturing processes, enabling seamless data exchange and collaboration between suppliers and customers. This trend enhances transparency, traceability, and overall efficiency in the supply chain. Staying updated with these trends and leveraging the latest advancements in CNC machining will help you source reliable providers and ensure your business remains at the forefront of innovation.

Sourcing reliable CNC machining services is essential for ensuring the quality and precision of your products. By identifying trustworthy providers, considering certifications and standards, learning from success stories, negotiating effectively, and staying informed about future trends, you can make informed decisions and build strong partnerships. Remember that finding the right CNC machining service provider is an investment in the success of your business. Take the time to research, evaluate, and communicate with potential providers to ensure they meet your specific requirements. By following these best practices, you'll be well-equipped to source reliable CNC machining services that deliver exceptional results. For more information and expert guidance on sourcing CNC machining services, feel free to contact us. Our team of experienced professionals is here to help you find the perfect solution for your needs.

Comments

Post a Comment