Introduction to High-Performance Shaker Screen

Introduction to High-Performance Shaker Screen

Are you tired of constantly replacing your shaker screens or dealing with lower quality screens that don’t perform as well as promised? Look no further, because we have the solution for you — High-Performance Shaker Screens. As a leading replacement shaker screen supplier, we understand the frustration and inconvenience that comes with using subpar screens.

That’s why in this blog post, we will introduce you to our top-of-the-line shaker screens and explain how they can greatly improve your drilling operations. From increased efficiency to cost savings, get ready to discover the benefits of using high-performance shaker screens in this informative article!

What Are Shaker Screens and How Do They Work?

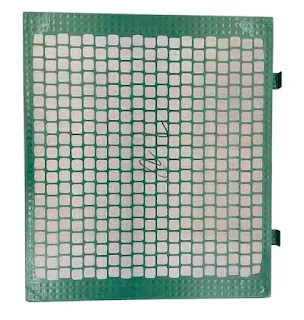

Are you in need of a high-quality Replacement Shaker Screen? Look no further because we’ve got you covered! But what exactly are Shaker Screens and how do they work? Well, Shaker Screens are used to separate solids and liquids in many industries, including oil and gas drilling, construction, and agriculture. They consist of mesh panels that vibrate in order to separate the materials. At our company, we provide durable and efficient Replacement Shaker Screen that are designed to withstand harsh working conditions. With our screens, you can ensure maximum productivity and minimize downtime. Choose us as your supplier and experience the difference!

The Importance of High-Performance Screens in Industrial Applications

As a Replacement Shaker Screen supplier, we understand the importance of high-performance screens in industrial applications. These screens are not only vital to the efficiency of the production process, but they also contribute to the safety of workers by preventing hazardous materials from escaping. When selecting a replacement shaker screen, it is crucial to consider key factors such as durability and filtration capacity. A high-quality replacement screen can significantly extend the lifespan of industrial machinery while improving the performance of the entire system. As a trusted supplier of top-tier replacement shaker screens, we are committed to providing our customers with a durable and cost-effective solution that meets their specific needs.

Materials and Technologies Used in Shaker Screen Manufacturing

As a replacement shaker screen supplier, it’s important to stay up-to-date with the latest materials and technologies used in their manufacturing. From high-quality stainless steel mesh to innovative composite materials, there is a wide range of options available for manufacturers to create durable and efficient shaker screens. With advancements in technology, shaker screens are being designed to better withstand harsh drilling conditions and provide improved filtration performance. As a supplier, it’s essential to understand the benefits and limitations of each material and technology to properly advise customers on the best options for their applications.

In conclusion, shaker screens are a vital component in many industrial applications and play a crucial role in the efficiency and productivity of various industries. We have learned about their function in separating and filtering materials, as well as the various materials and technologies used in their manufacturing. From high-performance screens to innovative manufacturing techniques, it is clear that the shaker screen industry is continuously evolving and striving for better results. As we have discussed, choosing the right replacement shaker screen supplier is essential to ensure optimal performance and cost-effectiveness. With the help of advanced materials and technologies, these screens can withstand harsh conditions and provide accurate results for a wide range of applications.

The importance of choosing a reputable supplier cannot be overstated, as it directly impacts the quality and reliability of your shaker screens. Whether you are in the oil and gas industry or any other industrial field, investing in high-quality shaker screens is crucial for achieving optimal results. So make sure to do your research and choose a supplier that values innovation, quality control, and customer satisfaction. With this knowledge at hand, you can confidently navigate the world of shaker screens with ease and reap its benefits for your business.

Comments

Post a Comment